Xiao Yang, Long, Leihang, Matthew Evans T., Zhou Hai, Liu, Hanlong, Stuedlein Armin W.. Effect of Particle Shape on Stress-Dilatancy Responses of Medium-Dense Sands[J]. Journal of Geotechnical and Geoenvironmental Engineering, 2019, 145(2): 04018105.

Keywords: Particle shape; Overall regularity; Strength; Friction angle; Stress-dilatancy equation.

High Lights:

Abstract:

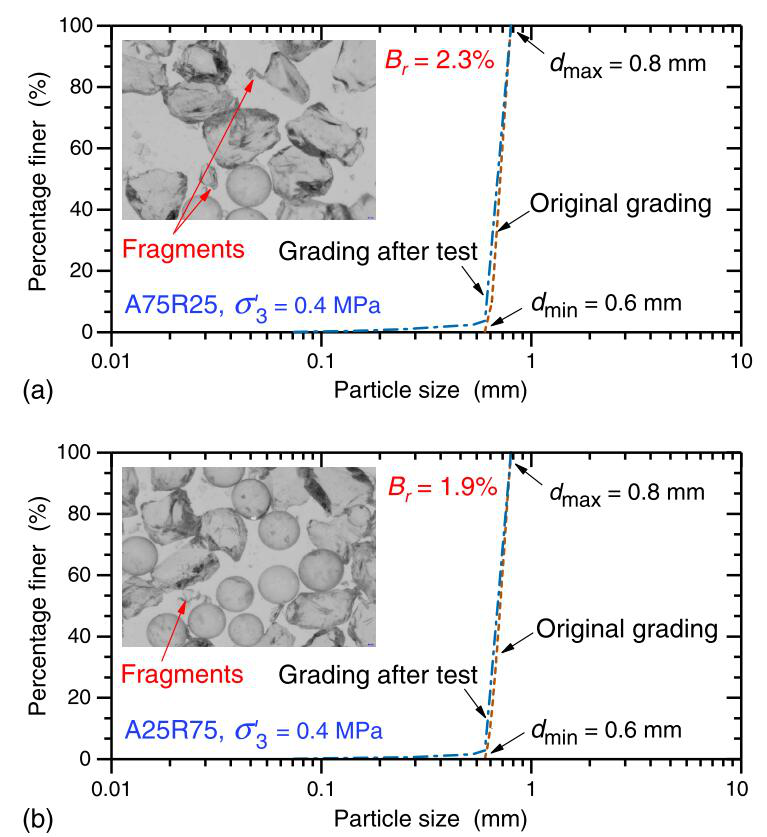

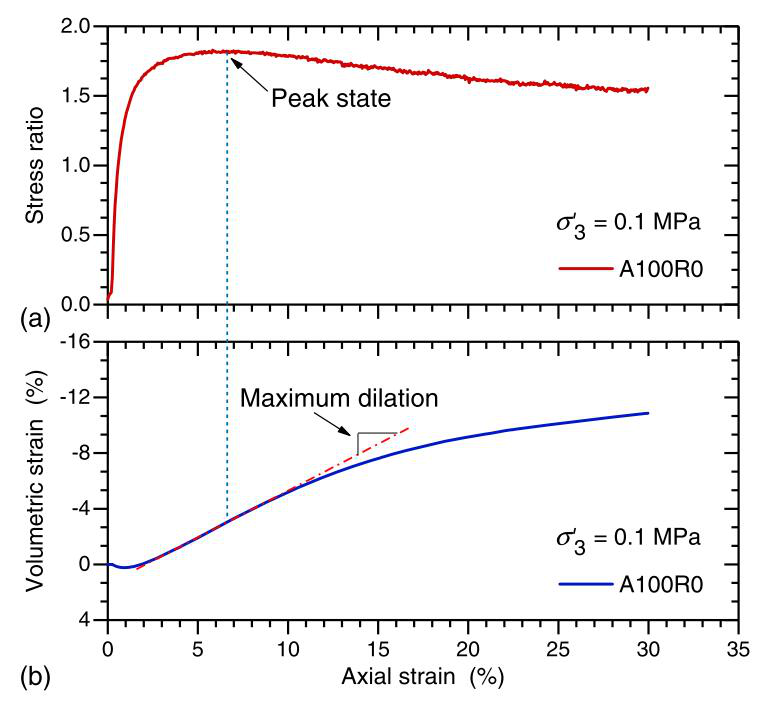

The effect of particle shape on the strength, dilatancy, and stress-dilatancy relationship was systematically investigated through a series of drained triaxial compression tests on sands mixed with angular and rounded glass beads of different proportions (0%, 25%, 50%, 75%, and 100%). A distinct overall regularity parameter was used to define the particle shape of these mixtures, which ranged from 0.844 to 0.971. The test results showed that all of the samples at an initial relative density of 0.6 exhibited strain-softening and volume-expansion behavior. It was found that the peak-state deviatoric stress, peak-state axial strain, and peak-state friction angle at a given confining pressure decreased with increasing overall regularity. The maximum differences in the peak-state deviator stress, peak-state axial strain, peak-state friction angle, excess friction angle, and maximum dilation angle due to changes in particle shape could be as much as 0.61 MPa, 5.4%, 8.6, 1.5, and 3° at a given confining pressure of 0.4 MPa. In addition, it was found that the slope of the relationship between the peak-state friction angle and maximum dilation angle was independent of the particle shape, whereas the intercept (i.e., the critical-state friction angle) was significantly influenced by the particle shape. A stress-dilatancy equation incorporating the effect of overall regularity was proposed and provided a good estimate of the observed response accounting for the different particle shapes investigated.

Resource:https://doi.org/10.1061/(ASCE) GT.1943-5606.0001994