[Geotechnical Engineering]

Li Chao, Zhong Zuliang, Liu Xinrong, Tu Yiliang, He Guannan. Numerical simulation for an estimation of the jacking force of ultra-long-distance pipe jacking with frictional property testing at the rock mass–pipe interface[J]. Tunnelling and Underground Space Technology. 2019, 89: 205-221.

Keywords: Ultra-long distance pipe jacking; Rock micro shield pipe jacking; Jacking force estimation; The displacement control method; FEM analysis; Rock–pipe interaction direct test

High Lights:

A new test specimen for simulating rock pipe jacking has been designed.

The frictional law under seven complex contact condition has been analyzed.

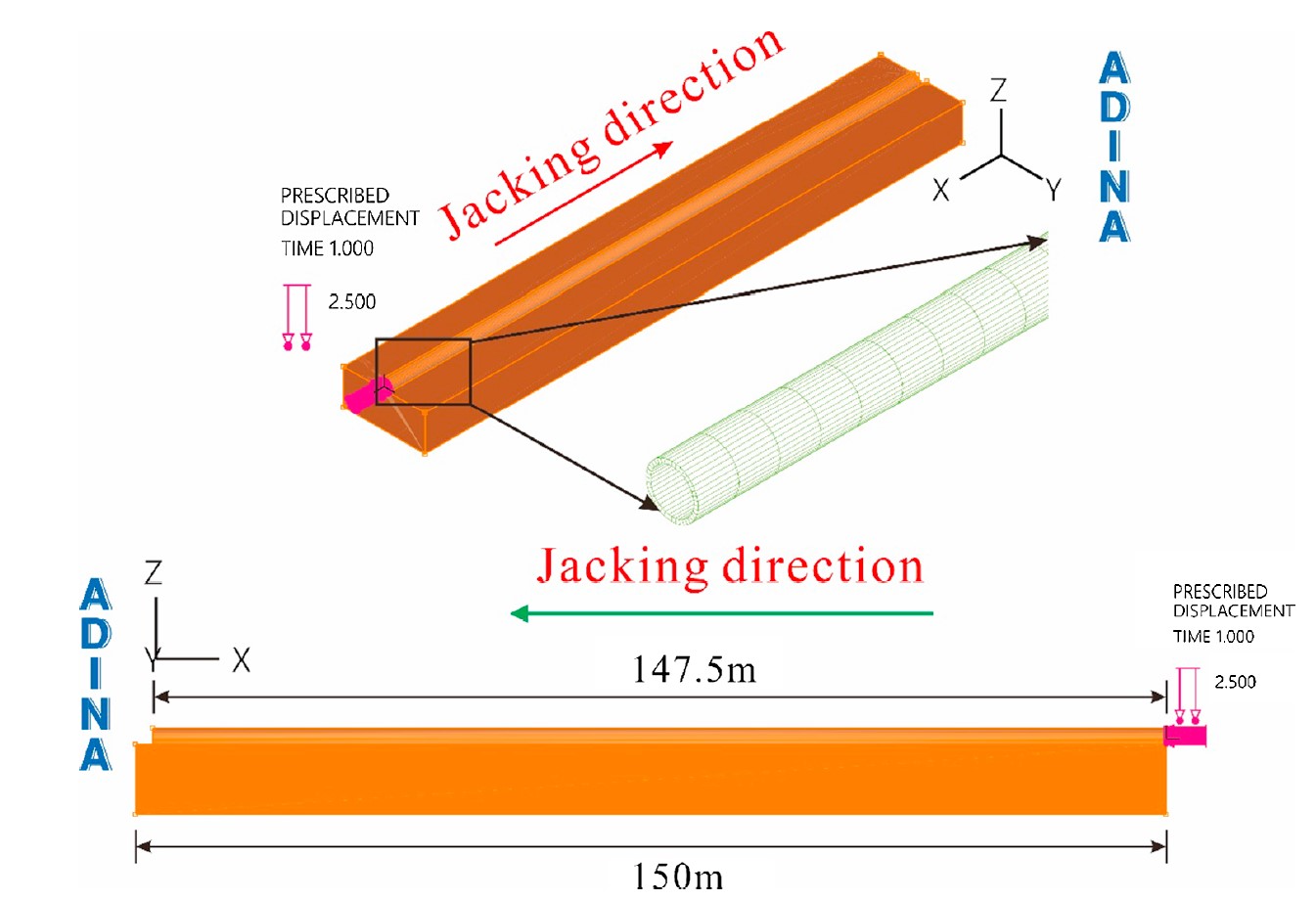

A three-dimensional simulation method for pipe jacking has been studied in ADINA.

The causes of the sudden drastic increase in jacking force have been verified in the study area.

Abstract:

In ultra-long-distance rock micro-shield pipe jacking, the pipe wall friction resistance is a key factor that determines the magnitude of the jacking force and the layout of the intermediate jacking stations (IJSs), whereas the pipe-rock contact condition is the critical factor controlling the pipe string wall friction resistance. This paper aims to reveal the variation law of the friction resistance between the outer wall of a large-section of concrete pipe string and the surrounding rock during construction via ultra-long-distance rock micro-shield pipe jacking. To that end, the shear friction behaviour and mechanical mechanism was investigated between sandstone and concrete pipe string walls under seven different complex contact conditions (primarily considering various combinations of the three substances, namely, extra-pipe in situ debris, bentonite slurry and sand-laden waste mud at the pipe-rock contact surface) through direct rock shear tests based on the actual pipe-rock contact condition at the Guanjingkou Water Conservancy Project in Chongqing. The average friction coefficient (AFC) of the residual phase of the contact surface under 7 contact conditions was obtained by friction testing. Combined with the contact situation between the surrounding rock and pipe strings at the stage of a rapidly increasing jacking force, a three-dimensional finite element model was established, and the displacement control method was used to simulate the jacking. The comparison with the field monitoring results shows that the numerical model can accurately predict the jacking force and verify the reliability of the AFC parameters in the numerical calculation. Therefore, the combination of indoor testing and the finite element method can be applied to study the jacking force for other ultra-long rock micro-shield pipe jacking applications.

Resource:https://linkinghub.elsevier.com/retrieve/pii/S0886779818307387