[Underground Engineering]

Yuxin Ban, Xiang Fu, Qiang Xie*. Revealing the laminar shale microdamage mechanism considering the relationship between fracture geometrical morphology and acoustic emission power spectrum characteristics[J].Bulletin of Engineering Geology and the Environment, September 2019, online.

Keywords: Shale; Fracture; Geometrical morphology; Acoustic emission; Power spectrum; Dominant frequency

Abstract:

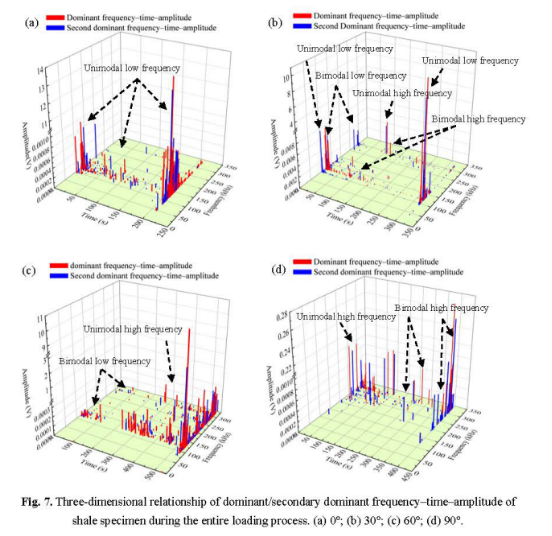

The corresponding relationship between the fracture geometrical morphology of laminar shale and the acoustic emission (AE) power spectrum characteristics was established to further reveal the shale microdamage mechanism. Laboratory Brazilian tests coupled with AE and digital image correlation (DIC) were conducted on black shale disks. The amplitude–time–dominant/second dominant frequency values of AE waveforms from the entire loading process were extracted with the function package PSD in MATLAB. The geometrical morphology of shale disk fracture is the result of a dynamic balance of microcracks, spatial anisotropy, local heterogeneity of the shale specimen, and the stress condition. There is a corresponding relationship between the distribution of dominant/second dominant frequency and shale internal microdamage. Four factors contribute to the shale specimen final failure, including the tearing of the shale matrix induced by local tensile failure (high dominant/second dominant frequency components at approximately 300 kHz), shearing on the bedding layer (middle dominant/second dominant frequency components at approximately 200–250 kHz), opening of the bedding layer induced by the weak structural plane, and friction on the microcrack surface (low dominant/second dominant frequency components at approximately 150 kHz). The fracture mainly controlled by the shale matrix tearing is flexible in profile because it is greatly affected by the competition of microcracks and local natural defects in the process of initiation and propagation. The fracture controlled by the opening of the bedding layer is a straight line with the rough surface and the fracture controlled by the shearing on the bedding layer is a straight line with the smooth surface. Finally, the fracture predominantly controlled by friction on the microcrack surface is generally arched. This work is helpful in providing considerations for depicting the probable fracture planar profile and explaining the microdamage mechanism, allowing for the enhancement of human control when constructing complex underground fracture networks in shale reservoirs.

Resource:https://www.researchgate.net/publication/335726701

https://link.springer.com/article/10.1007/s10064-019-01599-8