[Underground Engineering]

Yanru Zhao, Haiqing Yang*, Zhongkui Chen, Xiangsheng Chen, Liping Huang, Shuya Liu. Effects of jointed rock mass and mixed ground conditions on the cutting efficiency and cutter wear of tunnel boring machine[J]. Rock Mechanics and Rock Engineering. 2019, 52(5), 1303-1313. doi.org/10.1007/s00603-018-1667-y

Keywords: TBM Cutting, efficiency, Cutter wear, Jointed rock mass, Mixed ground

Abstract:

The cutting efficiency and wear of tunnel boring machine (TBM) cutters are two important parameters commonly used to estimate the boring performance and lifetime of the TBM in the tunneling process. These problems have been investigated by several researchers, whereas the influence of jointed rock mass and mixed ground condition on the cutting efficiency and cutter wear remains insufficiently understood. This study aims to elucidate the influence of rock mass and ground parameters on the cutting efficiency and cutter wear of the TBM by conducting a series of newly developed rolling boring tests on prefabricated joint sandstone samples with different orientations, spacings, and interlayers. Moreover, a numerical simulation is implemented through ANSYS software in order to verify the rationality of experimental results. The experimental and numerical results indicate that the optimal joint orientation is 30° for the TBM to intrude into a jointed rock mass. As joint spacing increases, the cutting efficiency decreases and the cutter wear increases. Furthermore, specific energy (SE) and cutter wear simultaneously reach their maximum values when the rock abrasivity index (RAI) is 60. Both the specific energy and cutter wear decrease with increasing specific strength. For the rock mass with a soft interlayer in mixed ground, the optimal dip angle is 45°. Additionally, the fitting formulas of SE and cutter wear in mixed ground are proposed to quantitatively illustrate the effect of RAI and interlayer strength on the cutting efficiency and cutter wear. The present study provides an improved understanding of rock-breaking mechanics, thereby making it possible for designers to adjust their design to enhance the TBM cutting efficiency.

Resource:https://link.springer.com/article/10.1007/s00603-018-1667-y

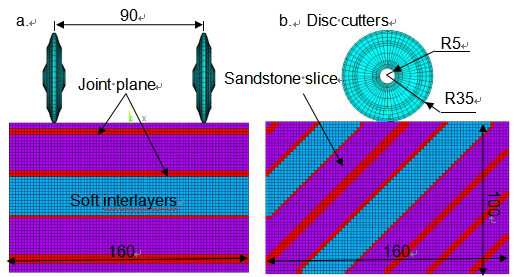

Fig. 4 Shape and meshes of rock and double cutters in the 3D-FEM model, (a) front view, (b) side view; unit in mm